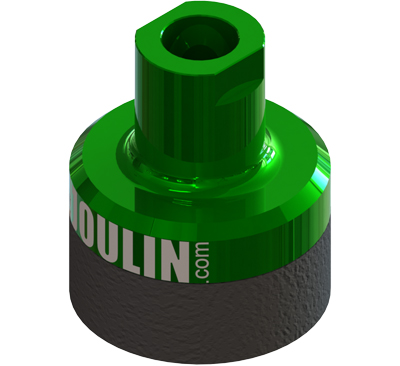

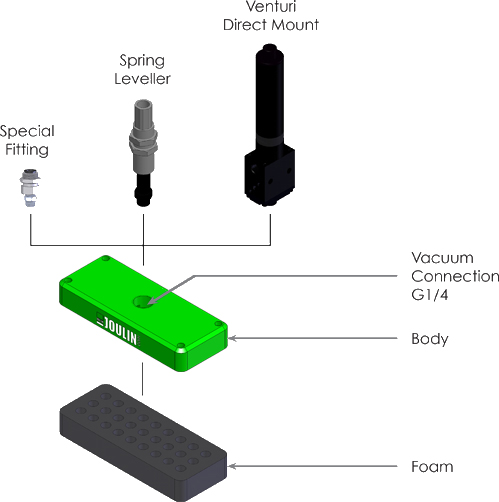

MiniGrip - Foam gripper

ALL INDUSTRIES - STANDARD

VERSATILE

- Foams adjust to smooth and rough surfaces easily

- Level compensators allow the Mini-Gripper to adjust for uneven layer heights without changing the mount

- Ability to pick a variety of products without adjustment

- Unlike larger grippers, with fixed hole locations, arrayed Mini-Gripper(s) may be moved to obtain a variety of pitches

- Provides a new way to obtain faster cycle times!

COMPACT

- Easily adaptable to current tight clearance applications comparable to vacuum cups

- No need for over sizing for small applications. MGs do the trick!

- The vacuum source can be installed directly to or close to the Mini-Gripper to maximize its capability and efficiency (If using the manifold (VM) vacuum source, it must be installed close to the gripper(s)

- Much smaller sizes compared to FlexiGrip grippers

EASY TO INSTALL

- Initial installation or changing a MG out for another is a snap!

- One 10mm compressed air fitting makes for quick push-lock connection to airline (airline - 10mm O.D.)

- Retrofit existing cups or existing pump system

| Style / Dimensions | GR25 | GR30 | GR40 | GR50 | GR60 | GR70 |

| C (Foam Thickness) - mm (in) | 12 (15/32) | 12 (15/32) | 15 (19/32) | 15 (19/32) | 24 (15/16) | 24 (15/16) |

| Weight w/o fitting - g (oz) | 23 (0.81) | 29 (1.02) | 44 (1.55) | 63 (2.22) | 86 (3.03) | 115 (4.06) |

| Holding Force N (lbs)* - 70% vacuum | ||||||

| Non porous... like steel | 4.7 (1) | 7 (1.5) | 11.1 (2.4) | 17 (3.8) | 21 (4.7) | 38 (8.5) |

| Semi porous... like wood | 3.8 (0.8) | 5.7 (1.2) | 9.1 (2) | 14 (3.1) | 18 (4) | 31 (6.9) |

| Porous... like cardboard | 3.5 (0.7) | 5.2 (1.1) | 8.3 (1.8) | 11 (2.4) | 13 (2.9) | 17 (3.8) |

| Vacuum consumption... Nl/s | 0.06 | 0.07 | 0.09 | 0.12 | 0.14 | 0.17 |

Forces and flow data given as a design help; these may vary a lot depending the surface

| Overall Dimensions | 20x80 | 20x120 | 40x60 | 40x100 |

| Dimension C - mm (in) | 12 (15/32) | 12 (15/32) | 15 (19/32) | 15 (19/32) |

| Dimension D - mm (in) | 10 (3/8) | 10 (3/8) | 30 (1-3/16) | 30 (1-3/16) |

| Dimension E - mm (in) | 70 (2-3/4) | 110 (4-11/32) | 50 (2) | 90 (3-17/32) |

| Weight w/o fitting - g (oz) | 49 (1.73) | 75 (2.65) | 71 (2.5) | 118 (4.16) |

| Holding Force N (lbs)* - 70% vacuum | ||||||

| Non porous... like steel | 16 (3.5) | 25 (5.6) | 31 (6.9) | 59 (13.2) | ||

| Semi porous... like wood | 14 (3.1) | 22 (4.9) | 27 (6.0) | 52 (11.6) | ||

| Porous... like cardboard | 12 (2.6) | 19 (4.2) | 23 (5.1) | 41 (9.2) | ||

| Vacuum consumption... Nl/s | 0.1 | 0.15 | 0.21 | 0.38 | ||

Forces and flow data given as a design help; these may vary a lot depending the surface

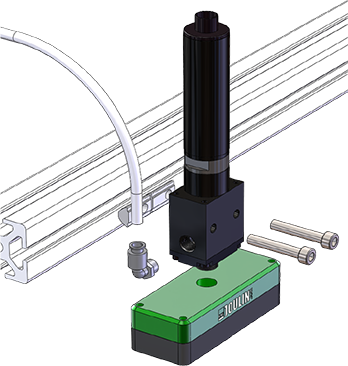

Venturi Direct Mount

This vacuum generation is an easy and quick installation option that gives higher flow for the larger MG grippers!

Use the 1STL for non-porous application to reduce compressed air consumption.

| VD- | 1ST |

| MG Option Venturi Direct Mount |

Integrated Vacuum Source : - 1ST = One Stage Regular Flow - 1STL = One Stage Low Flow |

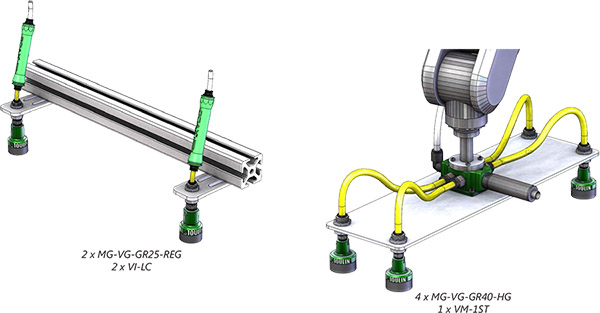

Venturi Inline

** This option is only used on non-porous application. **

** It can only be used with 20x80 and GR25 to GR50. **

This vacuum generation is an easy and quick installation option that gives high performance at low feed pressure!

| VI- | LC |

| MG Option Venturi Inline |

Integrated Vacuum Source : - LC = Low Consumption |

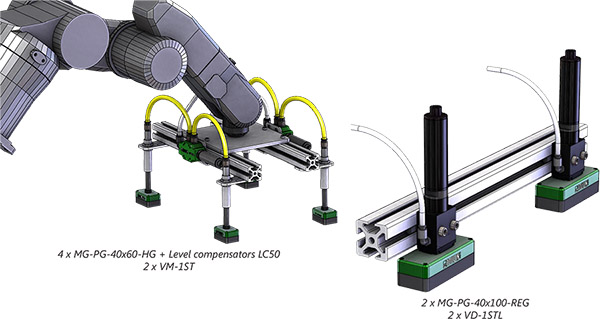

VENTURI MANIFOLD

This vacuum generation option is a quick and easy installation option that gives high flow and multiple gripper installation capabilities!

| VM- | 1ST |

| MG Option Venturi Manifold |

Integrated Vacuum Source : - 1ST = One Stage Regular Flow - 1STH = One Stage High Flow - 2 Stages - 3 Stages |

COMPARISON OF THE DIFFERENT VACUUM GENERATORS

| Type | Max vacuum kPa |

Feed pressure mPa |

Air consumption Nl/s |

Vacuum flow Nl/s at different vacuum levels -kPa | |||||||

| 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | ||||

| VM-1ST or VD-1ST | 65 | 0.6 | 1.79 | 2.36 | 2.17 | 1.94 | 1.65 | 1.32 | 0.85 | 0.42 | - |

| VM-1STH | 65 | 0.6 | 3.86 | 4.48 | 4.11 | 3.54 | 3.21 | 2.5 | 1.56 | 0.61 | - |

| VM-2ST | 75 | 0.6 | 1.75 | 3.3 | 3.0 | 2.6 | 1.7 | 0.9 | 0.6 | 0.5 | 0.35 |

| VM-3ST | 75 | 0.6 | 1.75 | 6 | 3.5 | 2.6 | 1.7 | 0.9 | 0.6 | 0.5 | 0.35 |

| VD-1STL | 65 | 0.6 | 0.85 | 0.99 | 0.94 | 0.87 | 0.83 | 0.76 | 0.59 | 0.38 | - |

| VI-LC | 75 | 0.6 | 0.44 | 0.69 | 0.55 | 0.42 | 0.28 | 0.23 | 0.16 | 0.12 | 0.08 |

RECOMMENDED MAXIMUM MGS PER VACUUM GENERATOR

| Cartridgesi | MiniGrip Sizes and Recommended Vacuum Flow (Nl/s) | |||||||||

| 20x80 | 20x120 | 40x60 | 40x100 | GR25 | GR30 | GR40 | GR50 | GR60 | GR70 | |

| 0.10 | 0.15 | 0.21 | 0.38 | 0.06 | 0.07 | 0.09 | 0.12 | 0.14 | 0.17 | |

| VM-1ST | 4 | 2 | 2 | 1 | 7 | 5 | 4 | 3 | 2 | 2 |

| VM-1STH | 6 | 3 | 2 | 1 | 10 | 8 | 6 | 5 | 4 | 3 |

| VM-2ST | 5 | 3 | 2 | 1 | 8 | 7 | 5 | 4 | 3 | 3 |

| VM-3ST | 5 | 3 | 2 | 1 | 8 | 7 | 5 | 4 | 3 | 3 |

| VD-1ST | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| VD-1STL | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| VI-LC | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 |

Level Compensation (non-rotating)

The Level Compensation option is designed to give the end user the ability to handle uneven layer surfaces.

This is a heavy duty non-rotating design with a high flow capacity.

| LC25 |

| MG Option - LC25 = 25mm [0.98”] Travel |

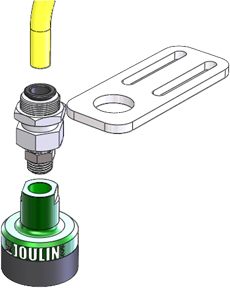

Special Fittings

This fitting assembly makes it easy to mount any Mini Gripper a bracket up to 9mm [3/8”] thick!

| FA- | 06 |

| MG Option Fitting |

Fitting Size :

- 06 = Fitting Assembly for 6mm inlet tube X R1/4 - 10 = Fitting Assembly for 10mm inlet tube X 1/4 |

Labeling

| MG- | VG- | GR25 | -REG |

| Range of the gripper | Technology :  Round: Round: - VG = Valve Gripper - PG = Port Gripper  Rectangular: Rectangular: - PGO = Port Gripper Oblong - PGR = Port Gripper Rond |

Style/Dimensions :  Round: Round: - GR25 - GR30 - GR40 - GR50 - GR60 - GR70  Rectangular: Rectangular: - 20x80 - 20x120 - 40x60 - 40x100 |

Flow : - REG = Regular - HG = High |

Examples :

MG-VG-GR60-HG

Valve Gripper 60mm O.D. footprint; High flow

MG-PGO-20X80-REG

Port Gripper 20mm x 80mm footprint; Oblong holes in the foam; Regular flow

English

English  Français

Français  German

German  Spanish

Spanish  Dutch

Dutch  中文

中文