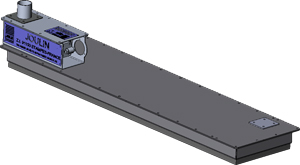

LUMBER GRIPPER - FOAM GRIPPER

ALL INDUSTRIES - STANDARD

CONCEPT

- Unique design

- Worldwide leader in the wood industry

- Foam pattern to fit your application

- Uneven surfaces

- Gripping power remains constant with single parts or entire layers

BENEFITS

- Saving up to 50% of energy with the Wave System™ (internal check valves)

- Easy and quick foam change

- Low maintenance

- Not sensitive to dust

- No filter required

EASY TO CUSTOMIZE

- Easy and inexpensive to manufacture to fit your needs

- Many options available

- Adjustable lifting capacity with different check valves

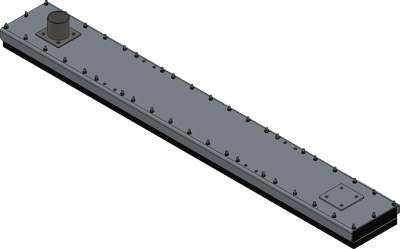

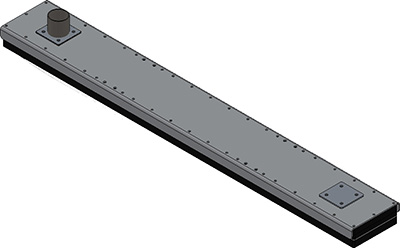

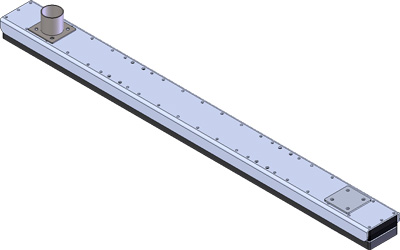

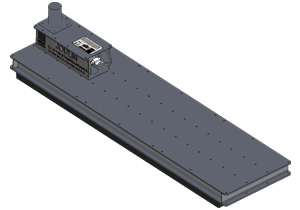

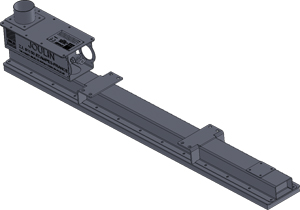

- Complete frame to support the grippers

- Quick delivery time

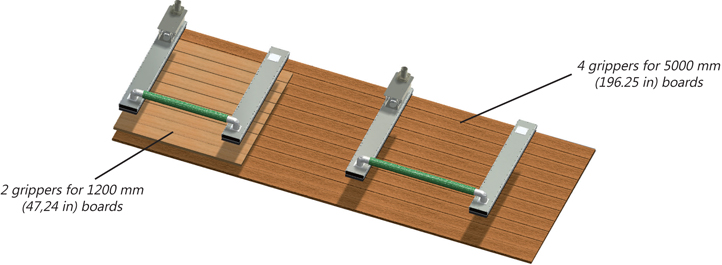

THE 3 STEPS FOR A GOOD INSTALLATION

First; position of the gripper:

The number of grippers depends on position and length of the boards

Second; what kind of gripper to use:

Each lumber industry has his own specifications

There are different internal and external designs to fit with each needs:

- External: The bodies of the grippers are made with different materials and design to fit with the working environment

- Flush: The most common one. Available in steel or aluminum

- Pan: Recommanded in the sawmills or pallet industries or where extreme conditions exist. The perimeter flange provides are very strong and safe design in case of collision

- Internal: All are equiped with the Joulin Wave System™ for energy savings and non sensitivity to dust or moisture

Third; lifting capacity:

Once we know the lumber specifications, we will choose the number of grippers and design

Different foam materials patterns and holes sizes are available

What is the Grade?

Industrial: Rough lumber or panels

Severe: Heavy dust present

Extreme: Extra heavy duty design for oversize beams or extreme installation conditions

• Flow reverser for quick release (light products, slip sheets)

• Blow off (light products, slip sheets)

• Flat, raised or flexible attachments

• Ejectors (venturi)

• Complete frame to support the grippers

Labeling

| LG- | VG- | 252 | -P21 | -N1200 |

| Range of the gripper |

Technology : - VG = Valve Gripper - PG = Port Gripper |

Version : - 616 - 441 - 252 - 99 - 29 - 27 |

Pitch : - P15 = 15 mm - P21 = 21 mm - P40 = 40 mm - P45 = 45 mm - P50 = 50 mm |

Foam Nominal (width of the layer) : - N1200 - N1300 - N1400 - N1500 - N1600 - etc, ... |

Exemple : LG-VG441-P21-N1800

Préhenseur Lumber Gripper VG441, pas de 21 mm, nominal de la mousse 1800

English

English  Français

Français  German

German  Spanish

Spanish  Dutch

Dutch  中文

中文